Masterplat Plus Turntable stretch wrapping machines

Introducing the Masterplat range of turntables for pallet wrapping. Robopac’s expertise in industrial packaging has expanded the automatic and semi-automatic wrapping machines range with a reliable, robust solution for high production environments. The Masterplat PGS model with standard pre-stretch system reduces film consumption and provides excellent product protection. Masterplat is for companies that need high performance, material savings and easy parameter management. The new icon based graphic display and jog selector allows operators to set wrapping cycles fast, easy and intuitive.

read more

Available Models

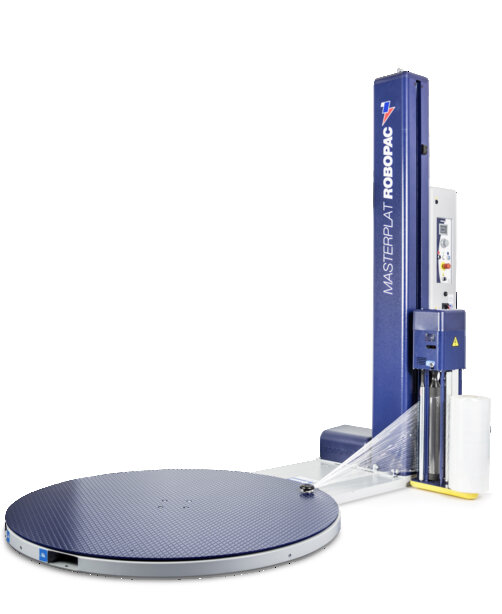

Masterplat Plus

The Masterplats are the latest range of Turntable Pallet Wrappers from Robopac.

Designed using the best features from the Ecoplats with the performance of the Rotoplats.

BENEFITS

- Excellent compromise between economic savings and performance

- Pallet stabilization

- Ease of use thanks to the user friendly panel

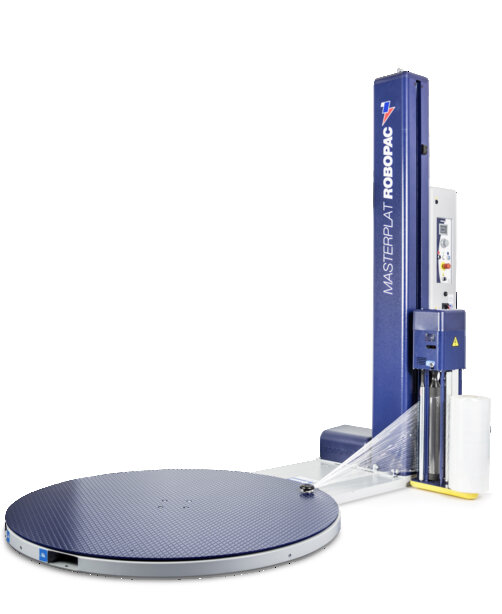

Masterplat Plus Inox

The Inox version of the Masterplat range is designed to ensure maximum corrosion resistance and hygiene in applications where cleaning and sanitization are essential.

It is the ideal solution for companies operating in the food, chemical, and pharmaceutical sectors, where the reliability of stainless-steel surfaces is a decisive factor.

BENEFITS

- The perfect solution for companies working in the food industry

- Greater resistance to oxidation and corrosion

- Stainless steel material for environments with a high humidity level

- Possible version for temperatures up to -30°C

Masterplat Plus Freezer

The Freezer version of the Masterplat range is engineered to deliver reliable performance even at low operating temperatures, making it ideal for companies in logistics, food processing, and the cold-chain sector.

Its structure and components are optimized for extreme conditions (-30°), ensuring continuity and reliability of wrapping cycles in refrigerated environments.

BENEFITS:

- Working temperature up to -30°C

- Ideal for food products

- Silicone cables suitable for low temperatures that ensure long life

DETAILS

FRD CARRIAGE

Film carriage with mechanical brake manually adjustable to set the film tensioning. Brake engagement- release device to facilitate hooking the film to the base of the pallet.

PGS CARRIAGE

The PGS film delivery device is equipped with a powered fixed gear (250%) pre-stretch system. A wide range of additional gear sets can also be purchased (150%-200-300%).

3,5 Inches colour graphic display

Parameter selection by jog: programming of the cycles in a simple and intuitive way

overview

Discover more on our app Robopac HMI

Try the Rotoplat, Masteplat Plus & Robot S7 user friendly control panel on your devices.

Masterplat Plus

option & data sheet

R-Connect

Innovation and connection for customer service: the tranquillity of maximum productivity as a result of constant monitoring of proper machine operation.

Powerful, plug & play and user friendly, R-Connect is a “turnkey” system for the end-user: the main advantage is total “peace of mind”, which is absolute tranquillity regarding machine operation, which includes production performance verification and optimisation of all management costs.

In fact, the system minimises machine downtime and manages maintenance operations better, also providing an immediate troubleshooting procedure, until the full and remote upgrade of the machine’s management software is completed.

ramps

Ramps for easy loading with hand pallet truck

Net film carriage

This carriage is used in all those sectors where product transpiration is required (fruit, vegetables, etc.)

Top presser

Top presser for the stabilization of light products.

Available in two versions: mechanical and pneumatic.

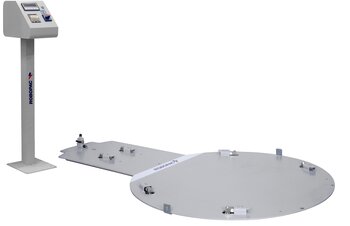

Weighing kit

Weighing frame kit for turntable machines.

|

Max load weight |

kg | 1200 std. 2000 opt. (Ø1500) / 2000 std. 2500 opt. (Ø1650-Ø1800) |

| Sensibility |

±0,2 |

|

|

Integrated printer |

opt. | |

| Compatibility | Ecoplat Plus (Ø1500) / Ecoplat Plus, Masterplat Plus, Rotoplat, Technoplat CS/CW (Ø1650) / Masterplat Plus, Rotoplat, Technoplat CS/CW (Ø1800) | |

|

Power supply voltage |

V |

110-240 V (1Ph) |

|

Power supply frequency |

Hz | 50/60 |

Technical features

| Turntable diameter | mm |

1650 std. 1800 opt. |

| Max load weight | kg | 2000 std. 2500 opt. |

| Turntable speed | rpm | 5÷12 |

| Carriage up-down speed | m/min | 1,4÷4 |

| Maximum product dimensions (LxW) | mm |

1000x1200 std. 1200x1200 opt. |

| Maximum product height | mm | 2200 std. 2400/2800/3100 opt. |

| Film carriage type | FR, FRD, PGS | |

| Film stretch | manual (FRD), adjustable from panel (PGS) | |

| Film pre-stretch |

n.a. (FRD), fixed 250% std. (PGS) |

|

| Forklifting | front and rear | |

| Power supply voltage | V | 230 V 1Ph |

| Power supply frequency | Hz | 50/60 |

| Installed power | kW | 1,5 (FRD) / 1,9 (PGS) |

| Max reel dimensions | mm |

500x300 |

| Max reel weight | kg | 20 |

| Film thickness | μm | 17÷35 |

Technical features

| Turntable diameter | mm |

1650 |

| Max load weight | kg |

2000 |

| Turntable speed | rpm | 5÷12 |

| Carriage up-down speed | m/min | 1,4÷4 |

| Maximum product dimensions (LxW) | mm |

1000x1200 |

| Maximum product height | mm | 2200 std. 2400/2800 opt. |

| Film carriage type | FRD, PGS | |

| Film stretch | manual (FRD), adjustable from panel (PGS) | |

| Film pre-stretch |

n.a. (FRD), fixed 250% std. (PGS) |

|

| Forklifting | front and rear | |

| Power supply voltage | V | 230 V 1Ph |

| Power supply frequency | Hz | 50/60 |

| Installed power | kW | 1,5 (FRD) / 1,9 (PGS) |

| Max reel dimensions | mm |

500x300 |

| Max reel weight | kg | 20 |

| Film thickness | μm | 17÷35 |

Technical features

| Turntable diameter | mm |

1650 |

| Max load weight | kg |

2000 |

| Turntable speed | rpm | 5÷12 |

| Carriage up-down speed | m/min | 1,4÷4 |

| Maximum product dimensions (LxW) | mm |

1000x1200 |

| Maximum product height | mm | 2200 std. 2400 opt. |

| Film carriage type | FRD, PGS | |

| Film stretch | manual (FRD), adjustable from panel (PGS) | |

| Film pre-stretch |

n.a. (FRD), fixed 250% std. (PGS) |

|

| Forklifting | front and rear | |

| Power supply voltage | V | 230 V 1Ph |

| Power supply frequency | Hz | 50/60 |

| Installed power | kW | 1,5 (FRD) / 1,9 (PGS) |

| Max reel dimensions | mm |

500x300 |

| Max reel weight | kg | 20 |

| Film thickness | μm | 17÷35 |